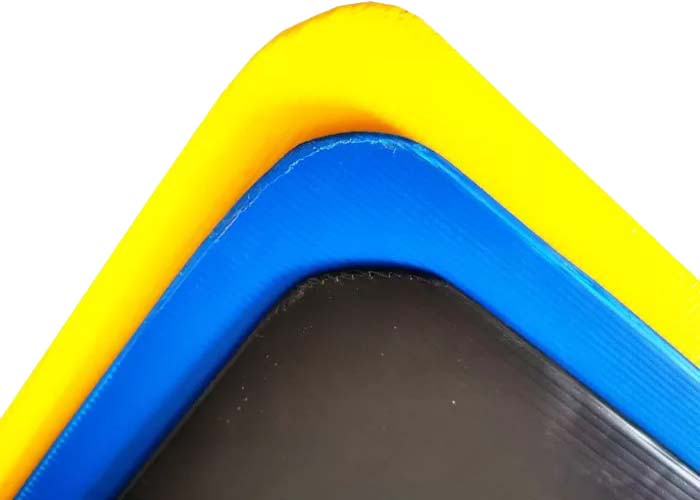

At Plasmix, we specialize in edge-sealed PP corrugated sheets that offer enhanced durability against moisture, UV exposure, and wear. Our advanced edge-sealing technology reinforces the most vulnerable part of the sheet, its edges, without compromising on flexibility or appearance.

Using high-quality polypropylene materials, we apply a precision coating along the sheet's edges, creating a strong barrier that prevents damage, delamination, and moisture ingress. Ideal for outdoor signage, protective packaging, and long-term industrial use, these sealed plastic corrugated sheets ensure maximum lifespan and performance in harsh environments.

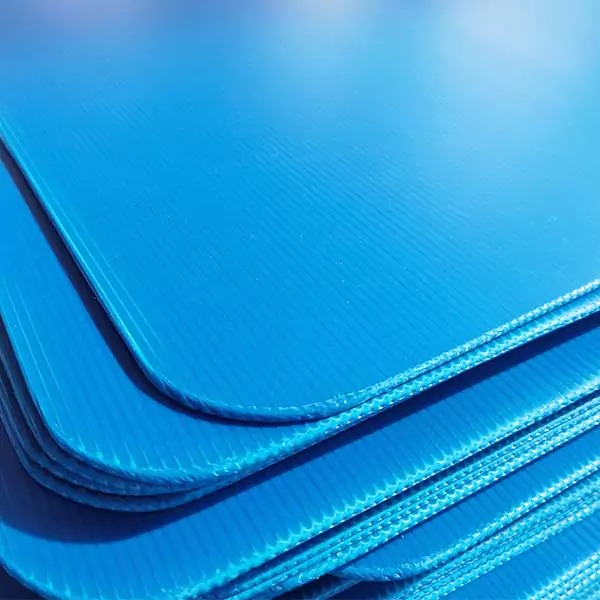

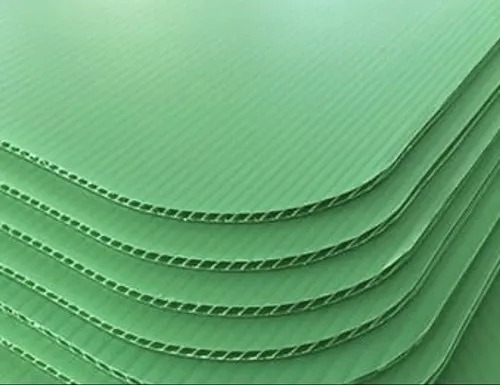

Edge-sealing corrugated sheets involve applying a protective coating along the edges to boost durability, weather resistance, and lifespan. While PP corrugated sheets are widely used in packaging, construction, and industrial applications for their lightweight yet sturdy nature, their edges remain vulnerable to moisture, humidity, and outdoor exposure. Plasmix’s edge-sealed polypropylene sheets solve this by offering reinforced protection for long-lasting performance.

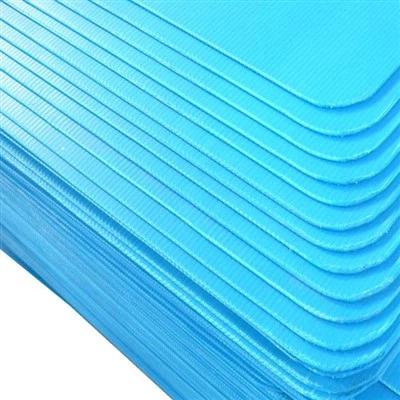

Edge-sealed PP corrugated sheets resist tearing and edge damage, delivering extended performance even in harsh environments—ideal for long-term industrial, packaging, or outdoor use.

Sealed edges eliminate sharp edges and loose particles, making corrugated plastic sheets safer to handle and reducing workplace injury risks during transport or assembly.

By preserving sheet integrity, edge sealing supports longer product life and better recyclability—promoting sustainable use and reducing material waste in packaging cycles.

Edge-sealed PP corrugated sheets offer improved structural strength, allowing them to bear heavier loads without compromising stability or durability—ideal for demanding industrial and logistics applications.