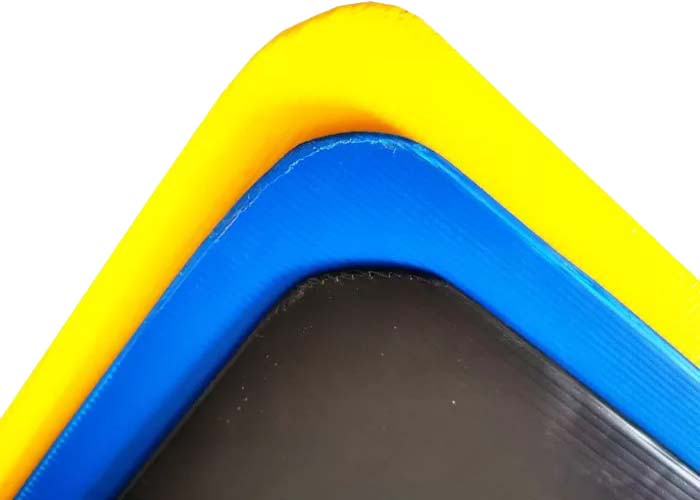

Ultimate Edge Protection with Edge Sealing Corrugated Sheets

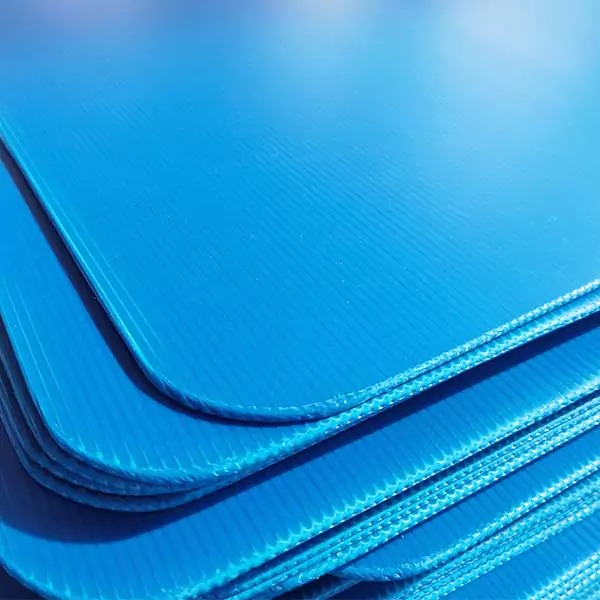

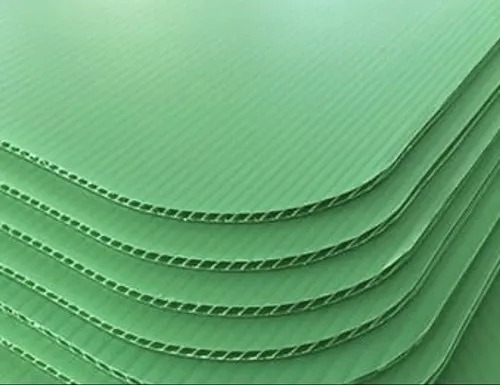

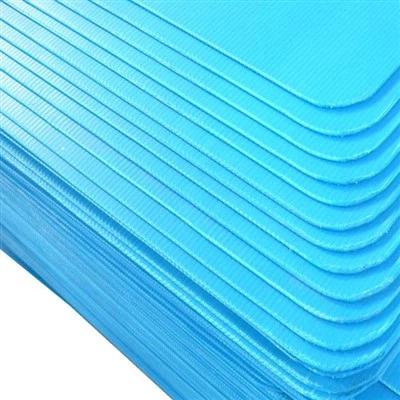

We at Plasmixsheets, who manufacture edge-sealing corrugated sheets, are aware that corrugated sheets' edges are particularly exposed to weather and wear and tear.With a strong barrier against moisture, UV light, and other harmful elements, our advanced edge-sealing procedure is designed to meet these problems head-on.

High-quality craftsmanship and state-of-the-art materials are used in our exclusive edge-sealing technology. Without sacrificing flexibility or visual appeal, Plasmix makes sure that each corrugated sheet is carefully treated to provide the best possible protection. Along the edges of the corrugated sheets, a specific sealer or coating is usually applied as part of the edge sealing procedure. In addition to reducing the chance of breakdown and shielding the edges from damage, this sealer acts as a barrier to keep moisture out of the material.