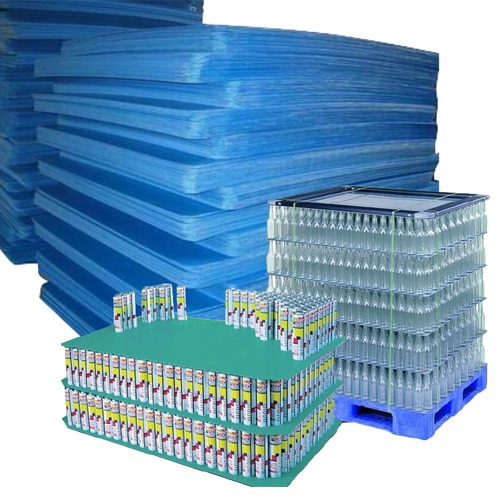

Also known as divider sheets, tier sheets, or spacer sheets, PP layer pads are rigid, flat plastic corrugated sheets used to separate and protect layers of products in pallet boxes, crates, and logistic containers. Manufactured using extruded polypropylene, they offer excellent impact resistance, moisture resistance, and structural integrity. These lightweight plastic sheets are ideal for stacking, organizing, and stabilizing goods during storage and transit.

PP layer pads are customizable in size and thickness to fit diverse packaging needs across industries like automotive, pharmaceuticals, food, and electronics. Their reusable and recyclable nature also makes them a sustainable choice for returnable packaging systems, reducing waste and overall packaging costs.

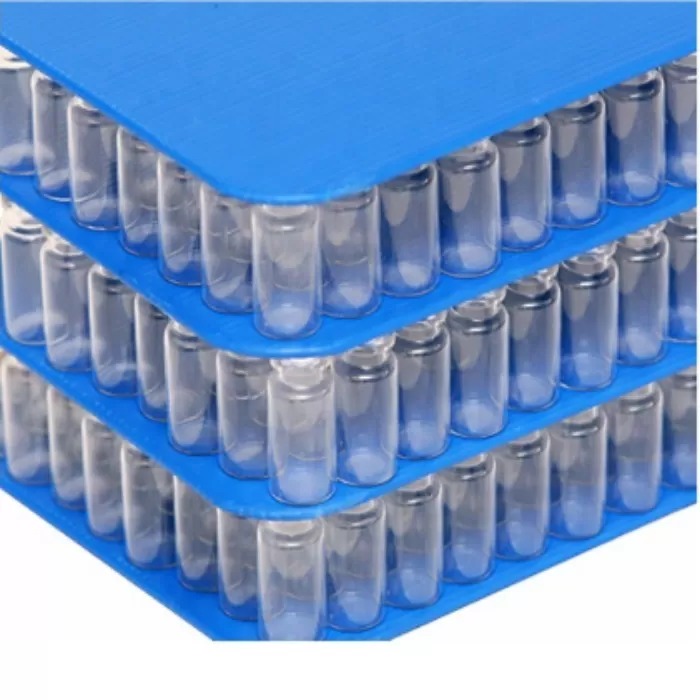

Plasmix delivers high-quality PP layer pads crafted from durable corrugated plastic sheets to meet demanding packaging and logistics needs. Made using extra-strength twin wall polypropylene sheets, these spacer sheets provide excellent protection against impact, compression, and vibration. Their shock-absorbing structure ensures reliable support for products during transport and stacking. Whether for automotive packaging, pharmaceutical partitions, or returnable packaging systems, our plastic divider sheets offer long-lasting performance with superior flexibility and strength.

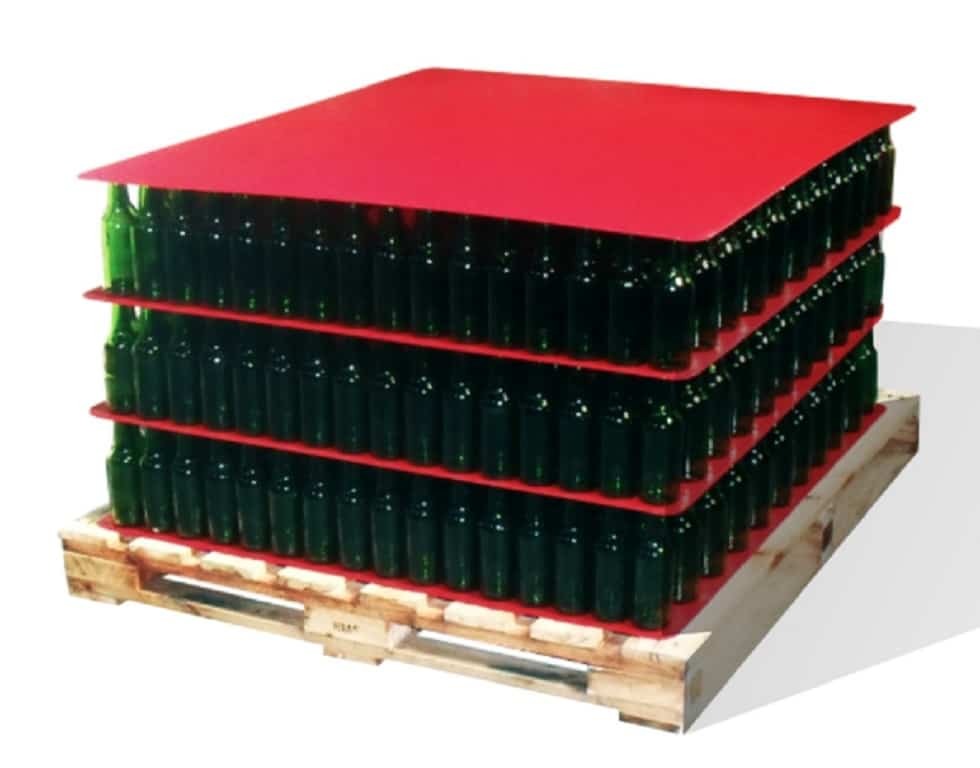

At Plasmix, we understand the need for reliable protection during storage and transit. Our PP layer pads and divider sheets shield products from impact, stacking pressure, and movement, ensuring they arrive damage-free.

Crafted from recyclable polypropylene, our layer pads offer a sustainable packaging solution. By using eco-friendly plastic sheets, we help businesses reduce waste and align with green goals.

Our corrugated plastic layer pads are designed for efficiency—minimizing damage, reducing material waste, and simplifying logistics. This results in lower operational costs and improved packaging performance.

Plasmix PP corrugated layer pads are engineered to withstand heavy loads without bending or losing shape, ensuring safe and stable product stacking during transport. Ideal for industrial packaging, these twin wall polypropylene sheets provide strong support for automotive components, machinery, and other heavy-duty applications, delivering unmatched durability under high pressure.